The most effective solution for removing VOCs and odors is thermal combustion

We offer thermal afterburners of various types, depending on the type of heat recovery:

- conventional

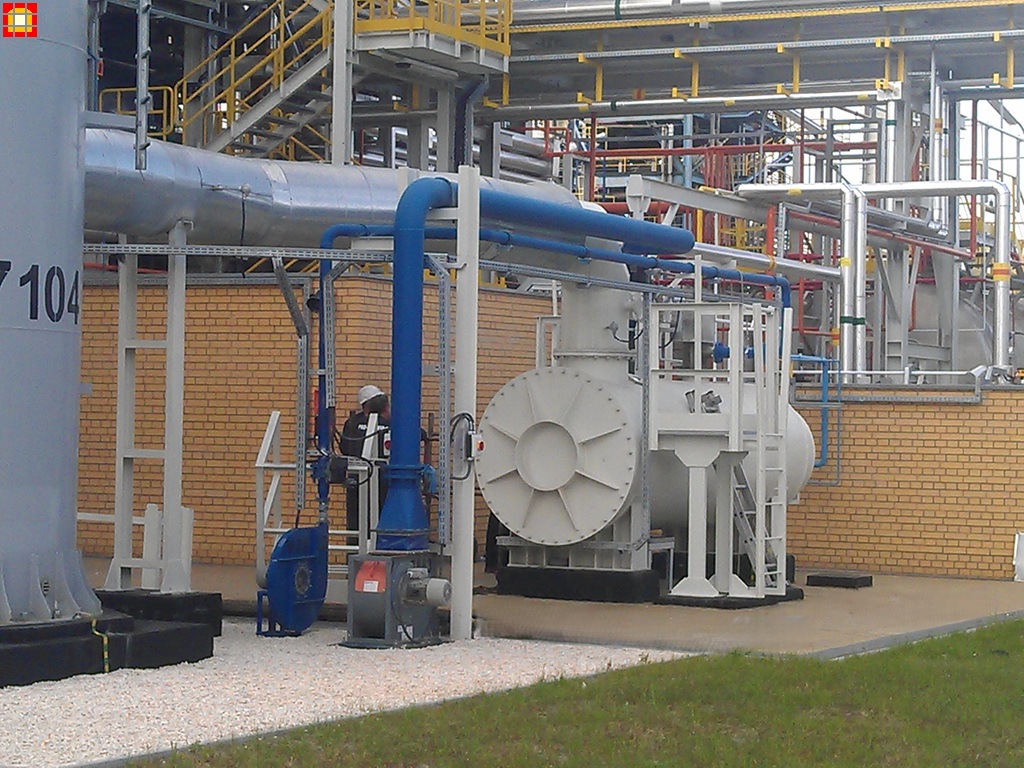

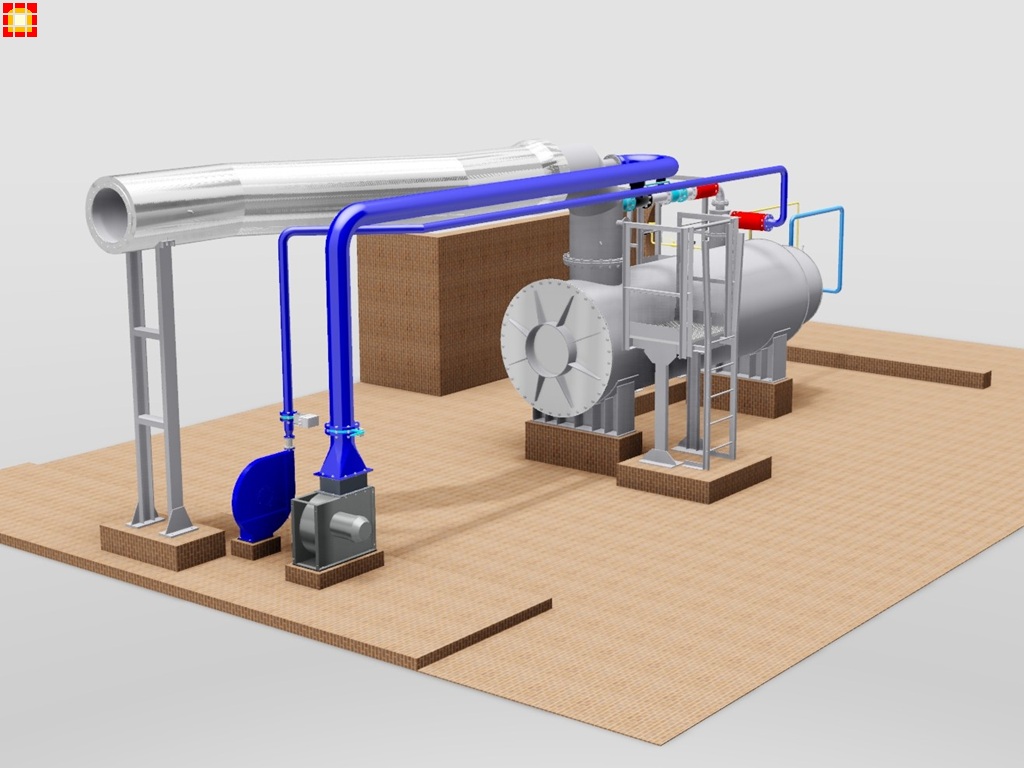

- recuperative

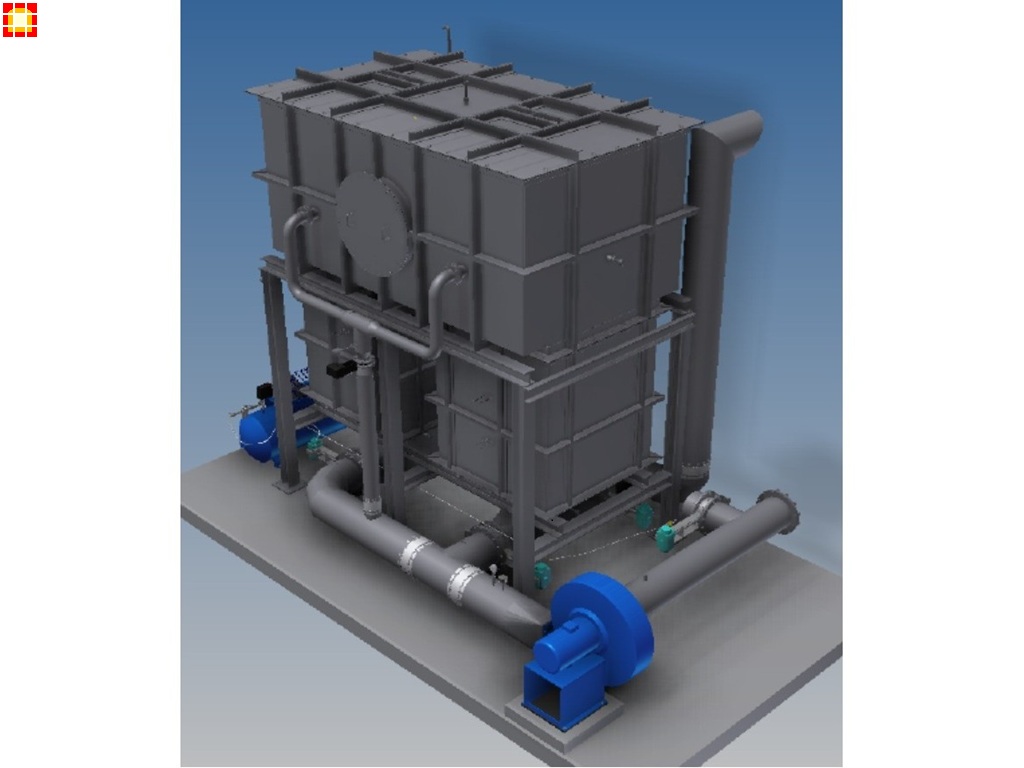

- regeneration (RTO)

Selecting a correct type of device depends on the gas flow rate and concentration of compounds for afterburning.

The main group of pollutants that can be thermally disposed of is volatile organic compounds (VOCs). We also offer devices for afterburning fumes of gasoline/petroleum /carbon/ aromatic hydrocarbons/ aliphatic hydrocarbons and other substances.

Thermal afterburning allows for achieving high efficiency of reducing emission of harmful substances at relatively low economic cost of the process.

Technical parameters:

- performance and dimensions depending on the order

- high efficency of VOC's destruction

- high energy efficiency of the device/ low consumption of additional gas to the burner

- types of pollutants: VOCs, CO, HCN and other gaseous pollutants

- combustion temperature: for standard compounds around 750˚C

- a device is fully automatically controlled,

Applicable in chemical, automotive, paper, furniture and other industries.

In particular, in such processes as:

- Glue

- Varnishing and coating

- Dry cleaning, surface cleaning

- Manufacture of footwear

- Manufacture of coating preparations, varnishes, inks, adhesives

- Manufacture of pharmaceutical products

- Printing

- Rubber processing

- refining oils

- fuelling tankers, ships, tanks

Detailed information can be obtained from:

Direct contact to project leader:

j_lisowicz@piecoserwis.com.pl

Contact to secretarial staff:

piecos@piecoserwis.com.pl

We invite You to read the article:

PI-4 Dopalacz termiczny regeneracyjny RTO - PUBLIKACJE

PI-27 Dopalacz gazów zrzutowych - PUBLIKACJE

PI-44 Dopalacz termiczny spalin procesowych - PUBLIKACJE

PI-45 Piec do wypalania węgla i grafitu w atmosfreze beztlenowej